Hengga Intelligent to Attend Canton Fair, Highlighting Brake Disc Lathe Technology

2025-03-22

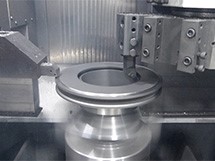

The LYV-SD500 brake disc CNC turning machine is setting new standards in the manufacture of brake discs and similar components, offering unparalleled efficiency and precision. By enabling rough and fine machining in a single setup, this machine uses dual-tool technology to simultaneously finish both surfaces of a brake disc. This innovative approach enhances production efficiency by more than 30% compared to conventional methods, making it an essential tool for high-volume brake disc production.

The machine features a vertical spindle and chuck design, supported by a thermal-symmetrical box-type ribbed structure in the bed and columns. The X/Z axes' wide-span design ensures robust resistance to heavy cutting forces, maintaining high precision in the automated mass production of brake discs and hub-type products. Engineered for large and medium-sized component processing, the brake disc CNC turning machine excels in delivering powerful, precise, and efficient machining, ideal for large-scale parts production.

The base and bed are crafted from integrally cast structures that undergo stringent aging treatments, providing high rigidity, excellent vibration damping, and toughness to ensure machine stability. The high-speed, high-precision, high-rigidity spindle head can be equipped with imported bearings, ensuring the reliability and precision of the spindle during prolonged heavy cutting, thereby extending its service life.

The X, Y, and Z axes feature a gantry column wide-span design, utilizing heavy-duty, high-precision, and high-rigidity linear guides. This setup, combined with large-spec long nuts and high-precision ball screws, reduces transmission deformation, improves transmission accuracy, and enhances support rigidity, enabling powerful, rapid cutting and grinding.

The automatic depressurization lubrication system provides centralized oil supply using an advanced intermittent supply method, delivering the right amount of oil to each lubrication point at the right time. This ensures the brake disc CNC turning machine operates smoothly over long periods without maintenance concerns.

Equipped with a programmable tool holder driven by a servo motor, the machine quickly adapts to different machining conditions, minimizing tool adjustment time and boosting productivity. It features the FANUC Oi-TF dual-channel system, known for its stability and reliability. The machine's integration of mechanical, electrical, and hydraulic modules is meticulously designed for rational layout, compact structure, complete enclosure, and ergonomic operation.

Hydraulic clamping with a built-in clamp detection function enhances safety and ensures concentricity requirements, reflecting the high level of automation. This machine is predominantly used for the mass production of brake discs, engine end covers, flywheels, gear blanks, and flange discs.

In summary, the LYV-SD500 brake disc CNC turning machine is a powerful asset for any manufacturer seeking to enhance production efficiency and precision. Our video demonstration showcases its remarkable capabilities in transforming brake disc production processes.