Hengga Intelligent to Attend Canton Fair, Highlighting Brake Disc Lathe Technology

2025-03-22

When operating a Brake Disc CNC Lathe, several important precautions must be taken.

Foremost, safety measures must be in place

Operators of Brake Disc CNC Lathe should wear protective gear, such as safety goggles, helmets, to minimize the risk of injury from moving machine parts.

safety measures must be in place

Secondly, it is crucial to configure the cutting parameters accurately.

This involves adjusting the cutting speed, feed rate, and cutting depth to ensure the best results. The interface of Brake Disc CNC Lathe displays all essential information and can be programmed to meet the required settings.

configure the cutting parameters accurately

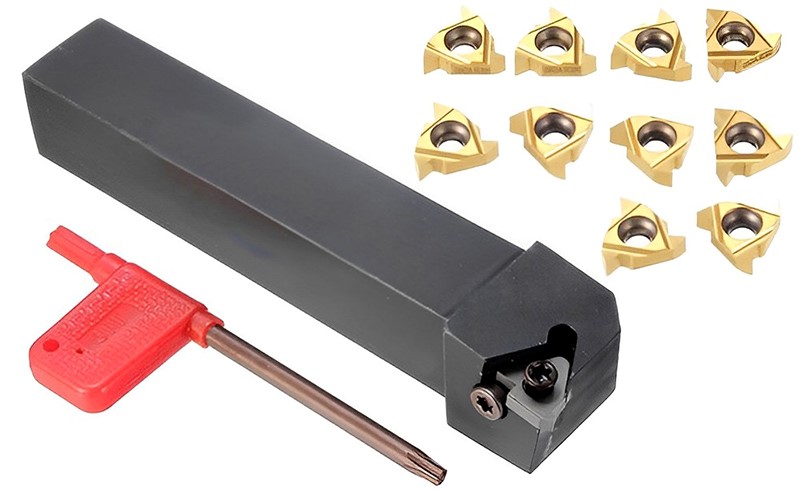

Thirdly, proper selection of cutting tools is vital.

Different types of turning tools are used for various materials and operations of brake discs, and operators must select the correct tool for the specific job.

proper selection of cutting tools is vital

Fourthly, regular maintenance is required to ensure the machine's optimal operation.

This includes cleaning the Brake Disc CNC Lathe, lubricating its components, and conducting regular inspections to identify any signs of wear or damage.

Lastly, it is crucial to verify the quality of the finished product.

This can be done using measuring instruments such as calipers and micrometers to check the dimensions and tolerances of the brake discs. This step is essential to ensure that the brake discs meet the necessary standards and are safe for use.

verify the quality of the finished product