Hengga Intelligent to Attend Canton Fair, Highlighting Brake Disc Lathe Technology

2025-03-22

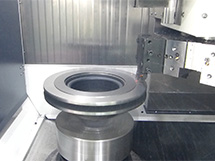

In the automotive manufacturing industry, the precision and efficiency of machining components such as brake discs and hubs are paramount. The brake disc lathe is a specialized, high-performance machine that addresses these exact needs with unparalleled accuracy and stability.

The brake disc lathe is designed with a thermosymmetric box-type ribbed structure for its bed and columns, which significantly enhances the machine's overall rigidity and absorption of vibrations. The X and Z axes feature wide-span designs and are equipped with high-precision, high-rigidity linear guideways and ball screws imported from leading manufacturers. This setup ensures that the machine maintains exceptional precision and stability, making it ideal for the simultaneous rough and finish machining of various disc and hub components.

This advanced lathe employs high-load sliding guides, providing high rigidity, accuracy, speed, efficiency, and reliability. It is widely applicable to industries such as mechanical manufacturing, motorcycles, electric motors, and automotive sectors for the machining of disc-shaped and gear components.

One of the standout features of the brake disc lathe is its ability to handle heavy loads thanks to its large cross-sectional area. This design boosts the machine’s rigidity, vibration absorption, and stability, ensuring precise cutting operations. The castings undergo a three-stage stress relief process and are filled with special materials at critical points to minimize thermal deformation and enhance vibration resistance.

The high-speed, high-precision, and high-rigidity spindle head can be equipped with imported bearings, ensuring long-term reliability and accuracy during heavy-duty cutting. The X-axis guideway uses a wide-span high-low rail design, which effectively shortens the distance between the spindle's center of gravity and the column, thereby ensuring excellent cutting rigidity.

Equipped with an automatic centralized lubrication system, the brake disc lathe ensures reliable and sufficient lubrication with automatic control of the lubrication cycle. Additionally, the machine can be fitted with high-rigidity hydraulic tool turrets, offering high reliability and repeatable positioning accuracy.

The CNC system, powered by the KND system, is specifically tailored for high-speed, high-precision machining. Each feed axis is driven by absolute servo motors, providing high precision and reliable performance. The protective interfaces are tightly sealed, preventing water, dust, and debris from contaminating the machine's bed.

This lathe significantly reduces the need for manual labor by approximately 50%, thereby lessening worker fatigue and lowering skill requirements. It is particularly suited for the rough and finish machining of automotive brake drums, brake discs, engine covers, brake discs, flanges, and other similar components.

In summary, the brake disc lathe combines cutting-edge technology with advanced engineering to deliver a machine that meets the high demands of modern manufacturing. Its high precision, efficiency, and reliability make it a vital asset for any automotive or mechanical manufacturing operation.