![]()

![]()

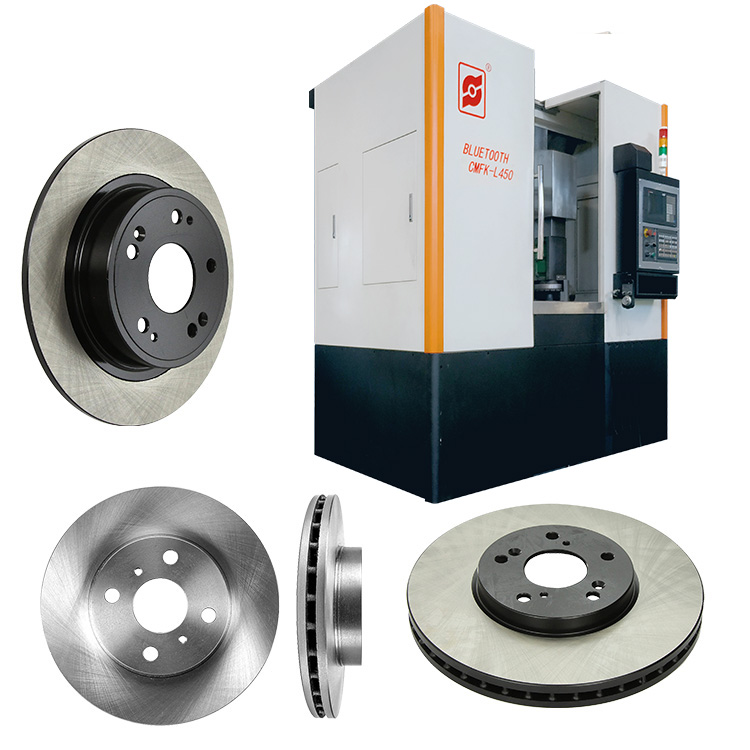

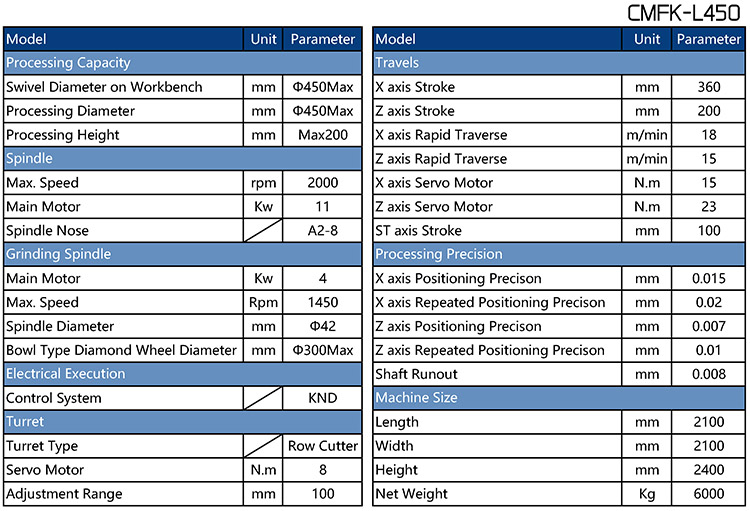

CMFK-L450 brake disc grinder is a high-precision and high-load vertical CNC lathe. Its X-axis adopts a positioning moving column structure, combined with an optimized structural design to reduce thermal deformation, improve shock absorption, and meet different needs for processing. guaranteed for a variety of complex structure workpieces, with high precision, high speed, high rigidity, novel protective shape, safety and environmental protection. suitable for high-speed turning processing in machinery manufacturing, automobile and other industries. The brake disc grinder adopts high-grade cast iron to optimize the design of the bed and parts, which has good seismic and tensile performance. The high-speed, high-precision, and high-rigidity spindle head adopts NSK bearings to ensure the reliability and accuracy of the spindle during long-term heavy cutting and enhance the service life of the spindle. The heat-treated and precision-ground ball screws ensure excellent accuracy and durability. The brake disc grinder is equipped with an automatic lubrication device to facilitate timely lubrication of the machine. The tool of the machine adopts the imported eight-station electric turret tool rest, which can change the tool quickly and improve work efficiency. The numerical control system can choose an absolute position encoder system or a servo numerical control system according to the needs. The inner protective folding cover adopts a back-shaped structure to prevent chips and liquids from entering the inside of the protective cover and improve the service life of functional components. The internal protection is designed without false rails, the operation is more balanced, and the bearing seat is protected twice, which effectively improves the service life of the bearing.

![]()

![]()

![]()

![]()