![]()

![]()

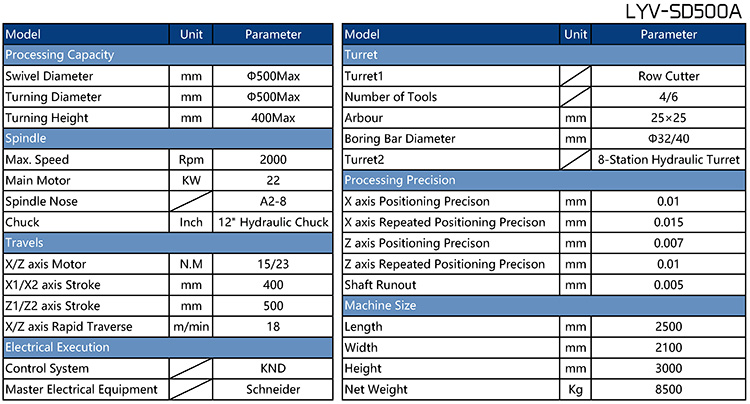

The LYV-SD500A brake disc machine is specially designed for the processing of brake discs/hub products. The bed adopts a thermally symmetrical box rib structure, and the X/Z axis adopts a large span design, which perfectly solves the resonance of rough and fine simultaneous processing. Problem, you can choose to increase the servo Y axis to realize the simultaneous processing of the double brake surfaces of the brake disc.

The bed body adopts a thermally symmetrical box-shaped rib structure, and the single-spindle double-pillar bed can easily realize the integrated rough and fine processing of the brake disc.

X-axis multi-track, multi-slider and large-travel special guide rail design, Z-axis modern new high-torque, no counterweight structure, Y-axis function can realize double-end surface finishing.

Perfectly solve the resonance problem of rough and fine processing at the same time, and increase the positive pressure dust removal device to ensure the stable accuracy of the equipment.

The brake disc machine adopts Taiwan HIWIN rolling high-precision, heavy-duty linear roller guide, replacing sliding with rolling, with small friction loss, sensitive response and high positioning accuracy.

Enlarge the main shaft unit assembly, the lubrication adopts imported high-grade grease lubrication, fully enclosed and maintenance-free.

The turning tool turret of the brake disc machine tool uses a high-load servo motor to perform tool change positioning. The tool change time for adjacent tools is only 0.5 seconds, and it only takes 2 seconds for the side tool.

The numerical control system of the LYV-SD500A brake disc machine is SYNTEC /FANUC /SIEMENS system; the spindle is driven by a high-power spindle servo motor; each feed axis is driven by an AC servo motor, which has high accuracy, high performance and reliability.

![]()

![]()

![]()

![]()